Overview

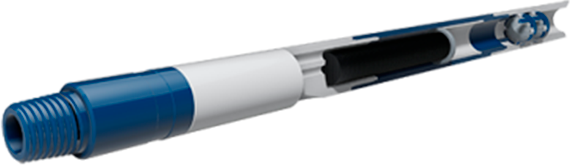

Tartan’s Venturi Junk Basket is designed to remove debris from the wellbore. Fluid is pumped down the tool string and out through nozzles, creating a vacuum within the tool. Wellbore debris is then sucked into the tool and remains trapped between the filter screen and catchers.

The tool nozzles are adjustable and easily changed to alter the flow rate and pressure to suit individual applications. The Venturi Junk Basket can be run with a motor and washover shoe for specific operations where rotation is required.

Application

- Cleans wellbore of junk and debris

- Retains debris from falling back into wellbore

- Catches large sized debris that is difficult to circulate outs

Features and benefits

- One run accomplishes debris cleaning

- Reduces rig time by eliminating a separate cleaning run

- Debris chamber may be enlarged by adding debris chambers

- Optional internal magnet to collect metallic debris

- Tool may be used with a mud motor

- Decreases operational costs

- Improves completions drilling efficiency

Fill out your information to receive the Venturi Junk Baskets data sheet.

Case Studies

MULTIFRAC™ D-J BASIN

Tartan MultiFrac systems successfully stimulated 18 months post-install.

ENERFRAC™ MONTNEY

Tartan successfully completes cemented EnerFrac™ ball-drop systems in the Montney.

MULTIFRAC™ UTICA

Tartan cemented MultiFrac limited entry ball-drop systems increase production by 12.5%.