Overview

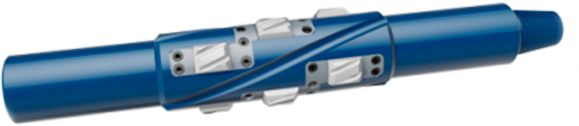

Tartan’s patented Rotating Scraper cleans the casing wall inside diameter (ID) while drilling out obstructions using Tartan’s downhole motors. The Rotating Scraper is connected directly to the bit box with a mill/bit installed at the opposite end.

Incorporating the Rotating Scraper with the downhole motor saves an additional tubing run, since casing wall cleaning is accomplished while drilling.

Application

- Clean casing ID to specifications while drilling out obstructions

Features and benefits

- Thoroughly cleans casing wall due to rotation

- Reduces rig time by eliminating a separate cleaning run

- Decreases operational costs

- Nine adjustable floating blades for multiple casing weights/IDs

- Improves completions drilling efficiency

- Operational in a push/pull scenario

Fill out your information to receive the Rotating Scraper data sheet.

Case Studies

MULTIFRAC™ D-J BASIN

Tartan MultiFrac systems successfully stimulated 18 months post-install.

ENERFRAC™ MONTNEY

Tartan successfully completes cemented EnerFrac™ ball-drop systems in the Montney.

MULTIFRAC™ UTICA

Tartan cemented MultiFrac limited entry ball-drop systems increase production by 12.5%.